A Deep Dive Into Metal Foundries: Crucial Info and Market Fads

Metal factories play a vital function in the production industry, changing basic materials right into vital components. The procedures entailed, from melting to quality assurance, are intricate and need precision. Recent developments are reshaping the sector, introducing automation and sustainability practices. Yet, difficulties linger, specifically relating to labor and product expenses. Comprehending these components is fundamental for realizing the current landscape and future direction of shops. What exists in advance for this fundamental market?

Comprehending the Steel Factory Process

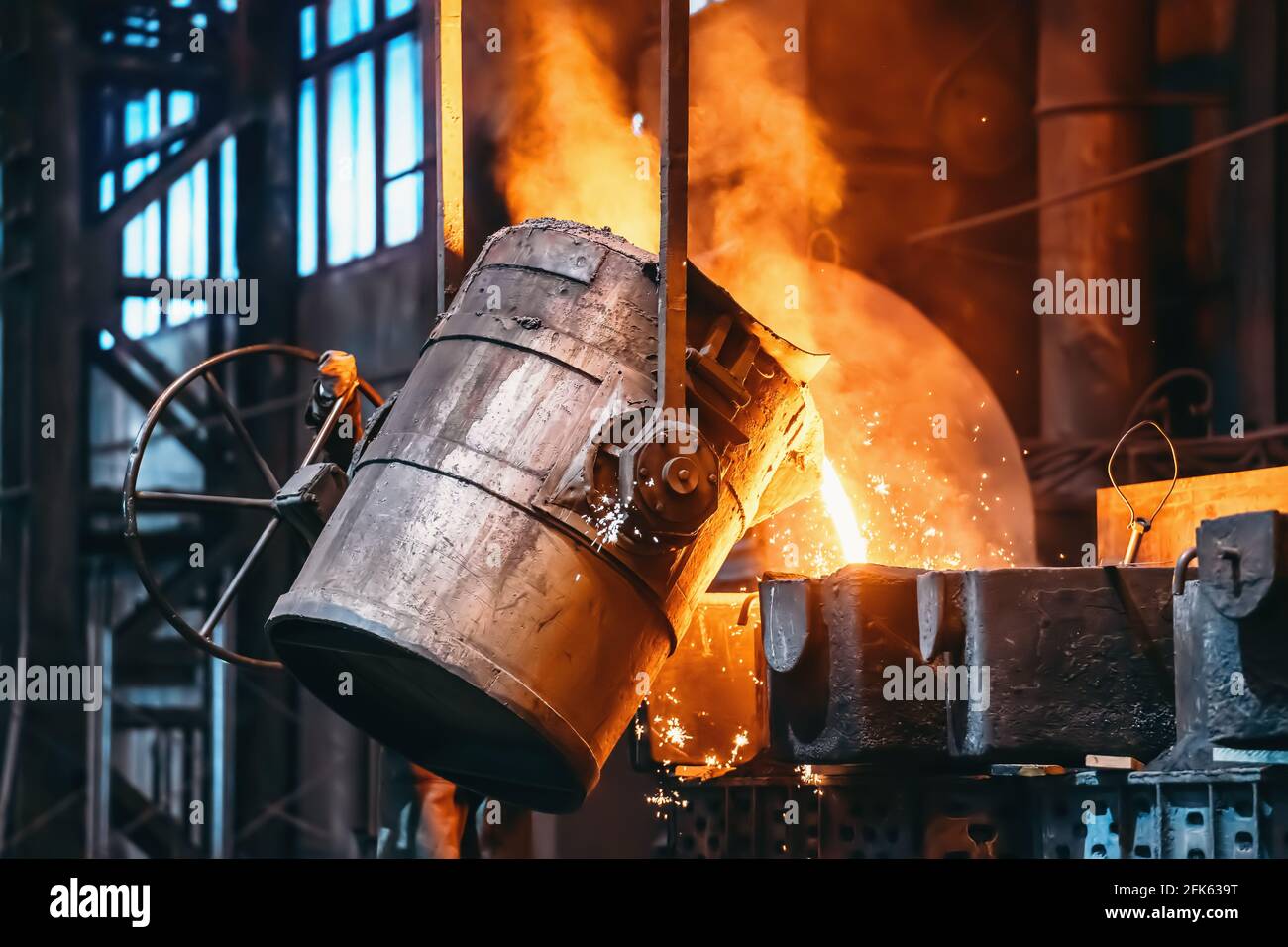

Although the steel factory process might seem complex, it focuses on a few fundamental stages that transform raw products right into completed metal products. Originally, basic materials such as metal ores, scrap metal, and alloys are sourced. These materials undergo melting in furnaces, getting to high temperatures to melt the metal. Once molten, the steel is poured into mold and mildews, where it strengthens and cools down right into the desired form

Following solidification, the castings are gotten rid of from the mold and mildews, bring about further processing. This may consist of cutting excess product, surface area finishing, and warmth therapy to boost properties. Quality control inspections are essential throughout the procedure to assure that the final items satisfy needed criteria and specifications.

Key Technologies Fueling Foundry Developments

The innovations in technology have greatly affected the steel foundry industry, driving developments that enhance performance and product high quality. Secret innovations reshaping this industry consist of automation and robotics, which simplify procedures and minimize labor prices, permitting accuracy in mold making and steel pouring. Furthermore, the adoption of 3D printing is changing pattern production, enabling intricate designs that standard techniques can not achieve. Furthermore, simulation software program has become a vital device, enabling foundries to forecast and fix potential spreading problems prior to manufacturing, therefore saving time and sources. The combination of IoT (Internet of Things) gadgets enhances monitoring and data collection, facilitating real-time changes to processes. Finally, innovations in metallurgy, such as the advancement of new alloys, are broadening the capabilities of shops to create more powerful and lighter components. Together, these innovations are transforming the landscape of steel shops, driving them towards better technology and competitiveness.

The Function of Quality Assurance in Steel Spreading

Quality control plays a critical role in steel casting, making sure that each part meets rigorous specifications and performance standards. This process entails a variety of methods, consisting of aesthetic inspections, dimensional measurements, and product testing - Aluminum Foundry. Shops employ quality assurance workers who monitor each stage of production, from raw product choice to the final product examination

By utilizing sophisticated technologies such as non-destructive screening and automated examination systems, steel factories can identify flaws early in the production cycle. This proactive technique decreases waste and decreases the probability of costly rework. In addition, adherence to market requirements, such as ISO certifications, enhances a foundry's dedication to high quality, boosting customer self-confidence and satisfaction.

Ultimately, reliable quality control not just improves the dependability and durability of cast elements but additionally drives constant renovation within the shop, fostering a society of excellence and innovation in steel casting processes.

Sustainability and Ecological Practices in Foundries

As metal shops progressively acknowledge their influence on the setting, a dedication to sustainability has ended up being important in their operational techniques (Aluminum Casting). Lots of foundries are executing energy-efficient innovations, such as electrical induction furnaces, which significantly reduce greenhouse gas discharges compared to traditional techniques. The fostering of recycled materials, specifically scrap steel, has actually also gotten traction, decreasing waste and saving natural resources

Additionally, water monitoring methods are being enhanced to minimize consumption and prevent contamination. Lots of factories are purchasing closed-loop systems that recycle water made use of in air conditioning More hints and cleaning processes. In addition, dust and emissions control innovations are being updated to guarantee compliance with environmental policies.

Future Fads and Obstacles in the Steel Foundry Industry

Arising fads in the metal shop industry highlight a change towards progressed innovations and ingenious practices aimed at improving performance and competition. Automation, including robotics and expert system, is progressively embraced to streamline operations and minimize labor costs. In addition, the assimilation of Industry 4.0 innovations helps with real-time data evaluation, enabling far better decision-making and predictive maintenance.

Nevertheless, challenges continue. The sector Metal Foundry deals with a knowledgeable labor scarcity, necessitating financial investment in labor force training and development. Moreover, rising and fall raw material rates and supply chain disturbances posture considerable hurdles. Environmental guidelines are becoming more stringent, pressing foundries to take on sustainable practices that can be pricey initially yet useful lasting.

Furthermore, the demand for lightweight and high-performance alloys is climbing, needing factories to innovate their materials and procedures. Balancing these patterns with continuous difficulties will be critical for the future success of the metal shop industry.

Regularly Asked Questions

What Is the Background of Metal Factories?

Exactly How Do Foundries Determine Metal Alloy Compositions?

Foundries figure out metal alloy make-ups through a combination of empirical testing, computer system modeling, and sector criteria. They examine wanted residential or commercial properties, application needs, and cost-effectiveness, guaranteeing the last alloy satisfies particular efficiency requirements for intended uses.

What Are the A Lot Of Usual Factory Products Utilized?

The most usual shop materials include cast iron, light weight aluminum, steel, brass, and bronze. These materials are favored for their toughness, flexibility, and toughness, making them ideal for various applications in production and building.

How Do Foundries Manage Hazardous Waste Disposal?

Factories handle contaminated materials disposal through rigorous adherence to ecological laws, using specialized containment systems, recycling efforts, and partnerships with qualified waste administration firms to assure compliant and risk-free disposal of poisonous products.

What Job Opportunities Exist in the Metal Shop Market?

Steel factories play a crucial duty in the production market, transforming raw materials right into essential parts. The steel foundry procedure may seem complex, it revolves around a couple of essential stages that transform raw materials right into completed steel products. The innovations in modern technology have actually greatly affected the steel factory sector, driving innovations that improve performance and product high quality. The background of steel shops dates back to ancient worlds, where artisans initially thawed metals to develop designs and tools. The metal foundry industry provides varied job chances, including roles in design, top quality control, procedures monitoring, and environmental conformity.